In the plastics industry, everyone will hear the term of blow molding. What is blow molding? Do you really know? Today, Yankang will take you to know more about it.

What is blow molding?

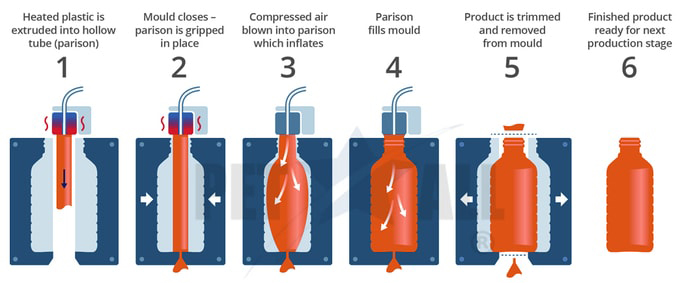

Blow molding is a method of forming hollow products by means of gas pressure to blow and swell hot melt embryos closed in the mould. The hollow blow molding is to extrude from the extruder and put the tubular thermoplastic blank which is still in the softening state into the molding mould. Then through the compressed air, using the air pressure to deform the blank along the die cavity, thus blowing into a short neck hollow products.

Hollow blow molding is the most important forming technology for producing hollow plastic products. Almost all thermoplastics can be used for hollow blow molding, such as polyethylene, PVC, polypropylene, polystyrene, linear polyester, polycarbonate, polyamide, cellulose acetate, and polyacid formaldehyde resin, etc.

With this molding technology, it can not only produce small volume bottles of several milliliters but also can produce thousands of liters of large-volume barrels and storage water tanks, as well as floating balls, automobile fuel tanks, and kayaks.

Yankang Plastic Machinery specialized in a 200L-20000L water tank blow molding machine. Customized blow molding machine also as well. Including plastic pallet, IBC tank, double ring drum, kayak, canoe, septic tank, solar inner, floating dock, etc. Here is the Product List.

What characteristics should blow molding products have?

1. Environmental stress cracking resistance: as a container, it has the ability to prevent cracking when it comes into contact with surfactant;

2. Airtightness (permeability resistance): refers to the characteristics that prevent the outward diffusion of oxygen, carbon dioxide, nitrogen, and water vapor.

3.Shock resistance: in order to protect the goods in the container, the products should have impact resistance that cannot be broken down from a one-meter height.

4. In addition, there are drug resistance, static resistance, toughness, and extrusion resistance.

5. Long lifetime.

What are the advantages of blow molding?

1. Fast molding speed, high production efficiency.

Yankang blow molding machine produces 18-20 large-capacity multi-layer water tanks per hour on average.

2. The hollow, double-walled structure can absorb and eliminate impact energy, a long lifetime.

3. Flexible design, with high functionality and low production cost.

4. The processing technology can change the thickness of the embryo, and the wall thickness is more stable than other molding methods.

5. During processing, the thickness of the product can be changed at will without improvement of the mold.

6. Low-pressure molding (the internal stress of the mold is much smaller than that of the injection molding), so as to improve dimensional stability, chemical corrosion resistance, and high-temperature performance.

7. Assembly diversity: self-tapping screw, die to insert, rivet expansion fastener.

8. Simple mold, low cost, and short processing cycle.

9. The sample mould with a low price can be produced quickly.

10. Energy Saving And Environmental Protection

The production process is more environmentally friendly than other molding processes.

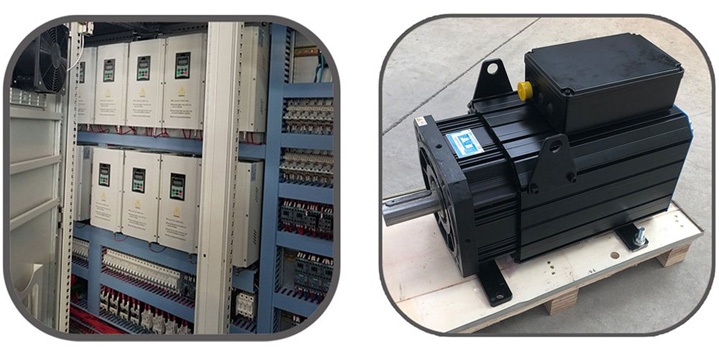

In addition, in terms of energy consumption, the blow moulding machine is more energy-saving.

During the design and production of the blow moulding machine, Yankang Plastic Machinery adopts advanced introduction heaters for die head and extruders, which can save 40%-50% energy. And adopt servo motor for clamping system, which can save 40% energy.

11. Blow moulding products have low requirements for the material.

The waste material cut from the blow-molded products can be put into production again after a certain treatment.

The material can be recycled and achieve material savings, reduce the cost.

After reading these, are you familiar with blow molding? Tomorrow, Yankang will continue to share with you the things of the blow molding machine. Please look forward to it!