Today we are going to share the information about the mixer operation specification.

The mixer is one of the important auxiliary machines of the blow molding machines.

Mixer staff must carefully read this « Mixer Operation Specification » before the operation. Master the working principle, structure, and performance of the machine, and maintain the mixer according to the standard.

Let’s go!

- The mixing personnel should be familiar with the proportion of raw materials in the factory and wear a dust respirator to mix materials when entering the site.

- After the mixing staff comes to work, they shall first hand over to the mixing staff of the previous shift. To know whether the raw material ratio has been changed or not and whether the machine is in normal operation. If there is any abnormality, inform the person in charge on duty immediately.

- Receive raw materials required for the shift according to the production plan.

- Check whether the mixer is energized and whether the switch is normal before mixing. Make sure the colors are separated into the corresponding color machine and start stirring.

- The first stirring time is 15 minutes, and then according to the needs of interval stirring.

- It is not allowed to dismantle the protective net and the feeding port of the machine while the machine is in operation. If necessary, the machine must be shut down and cut off.

- When changing colors, clean up the materials of the previous color, wipe them with an air gun and a cloth, and then change colors and stir them.

- Regularly check whether the screws of the mixer are loose and whether the belt is loose or seriously worn. Notice the class leader to deal with any abnormality.

- Keep the mixing workshop area in the strict implementation of 5S field management. Keep the floor and working area clean and tidy. Put the swept flooring material in the designated place after it is bagged and marked.

- Organize raw materials before leaving work, clean up the area I am responsible for, and finish the handover work.

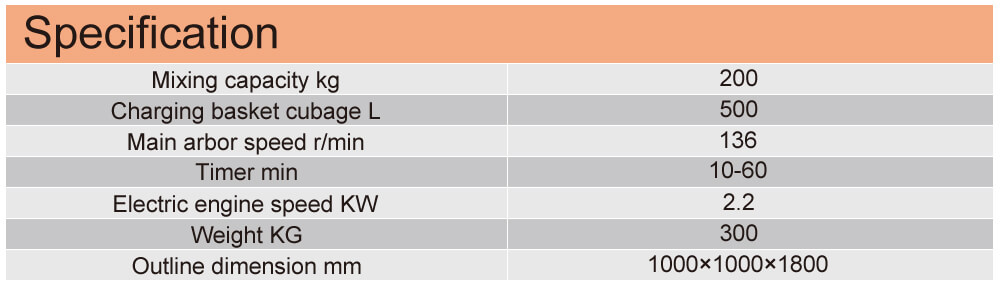

The mixer used by Yankang has the advantages of less floor space, large capacity, low power consumption, manual labor, convenient operation, and rapid and uniform mixing.

It has the following advantages:

- Vertical design: easy to control, easy maintenance;

- Easy to clean: stainless steel, easy to clean and not rust;

- Mixed evenly: The stirring speed is fast, can guarantee each batch of material is the same;

- Cost-saving: It has the advantages of small investment, quick effect, small occupation of land, high efficiency, and high benefits.

That’s all.

Share more:《Blow Molding Machine Crusher Operation Specifications》.