2000L Water Tank Blow Molding Machine

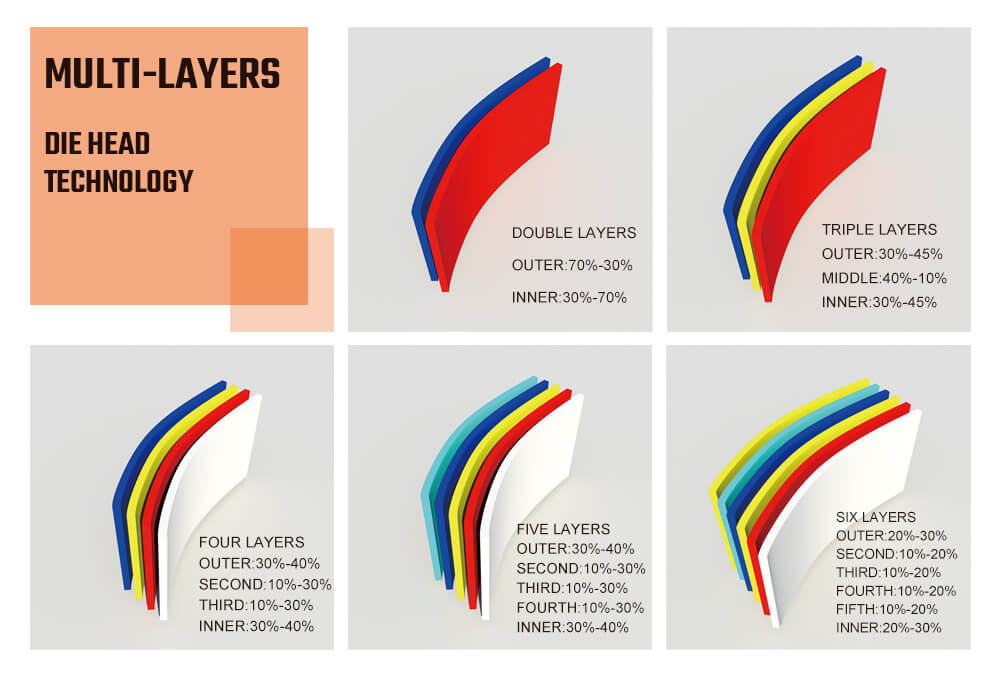

The 2000L water tank blow molding machine can be used to produce water tanks from 500L to 2000L in 1-6 layers.

Water Tank Daily Output:180-320PC

Delivery Date:3-4 Month

| Commodity | Output | Unit | Weight | Unit |

| 500L Tank | 16-18 | PC/H | 6-10 | KG |

| 750L Tank | 14-16 | PC/H | 10-15 | KG |

| 1000L Tank | 10-12 | PC/H | 16-20 | KG |

| 1500L Tank | 9-11 | PC/H | 20-30 | KG |

| 2000L Tank | 8-9 | PC/H | 30-40 | KG |

Applications of 2000L Water Tank Blow Molding Machine

The 2000L water tank blow molding machine can be used to produce water tank from 500L to 2000L in 1-6 layers.

Technical Parameter of 2000L Water Tank Blow Molding Machine

Output For Each Capacity

2000L water tank blow molding machine can use 500L,700L, 1000L,1500L, and 2000L blow molds.

Can be used for production:500L tank 16-18 PC/H,750L tank 14-16 PC/H,1000L tank 10-12 PC/H,1500L tank 9-12 PC/H and 2000L tank 8-9 PC/H.

For more production details:

| Capacity | Product | Unit | Weight | Thickness |

| 500L Tank | 16-18 | PC/H | 6-10KG | 2.5m |

| 750L Tank | 14-16 | PC/H | 10-15KG | 2.5-3m |

| 1000L Tank | 10-12 | PC/H | 16-20KG | 3-3.5mm |

| 1500L Tank | 9-11 | PC/H | 20-30KG | 3-4mm |

| 2000L Tank | 8-9 | PC/H | 30-40KG | 4-5mm |

Technical data for YK 2000L series

In the table below, the data of the blow molding machine of YK 2000L-3 layers, YK 2000L-4 layers, YK 2000L-5 layers, YK 2000L-6 layers are listed.

| Technical Data for YK 2000L Series | ||||||

| Model No. | YK 2000L-3 | YK 2000L-4 | YK 2000L-5 | YK 2000L-6 | ||

| Specifications | 3 layers | 4 layers | 5 layers | 6 layers | ||

| Extruders | Screw Diameter | ∮90*3 | ∮90*4 | ∮90/90/60/90/90 | ∮90/90/60/90/90 | |

| Motor | 55*3kw | 45*4kw | 45/45/18.5/45/45kw | 45/45/18.5/45/45kw | ||

| Plasticizing Capacity | 400kg/h | 400kg/h | 400kg/h | 400kg/h | ||

| L/D | 32/1 | 32/1 | 32/1 | 32/1 | ||

| Max Screw Speed | 60RPM | 60RPM | 60 RPM | 60 RPM | ||

| Die Head | Accumulator Capacity | 80L | 80L | 80L | 80L | |

| Heating Load | 83.2kw | 65kw | 71.9kw | 78.8kw | ||

| Max. Parison Weight | 60kg | 60kg | 60 kg | 60kg | ||

| Clamping Unit | Clamping Platen Size | 1700x1800mm | 1700x1800mm | 1700x1800mm | 1700x1800mm | |

| Max Mould Size | 1600x1900mm | 1600x1900mm | 1600x1900mm | 1600x1900mm | ||

| Clamping Force | 1800 KN | 1800 KN | 1800 KN | 1800 KN | ||

| Mould Thickness | 1010-1600mm | 1010-1600mm | 1010-1600mm | 1010-1600mm | ||

| Hydraulic System | Hydraulic Drive Motor (Main) | 42kw | 42kw | 42kw | 42kw | |

| Hydraulic Drive Motor (Parison Control) | 7.5kw | 7.5kw | 7.5 kw | 7.5 kw | ||

| Oil Tank Capacity | 1200L | 1200L | 1200L | 1200L | ||

| Machine Weight | 38 Ton | 42 Ton | 46 Ton | 50 Ton | ||

| Dimension | L x W x H | 11m*13m*6.2m | 11m*13m*6.2m | 11m*13m*6.2m | 11m*13m*6.2m | |

| Total Power | 384kw | 448kw | 495 kw | 516kw | ||

| Average Power Consumption | 192kw | 235kw | 255 kw | 280kw | ||

Configuration of 2000L Water Tank Blow Molding Machine

For example:

Use original SIEMENS control systems. Guarantee high quality, safe and stable operation. At the same time, it provides after-sales international services.

For more advanced configurations, please refer to the following figure.

| SR | Description of Parts | Brand | Origin |

| 1 | PLC | SIEMENS | Germany |

| 2 | Touch Screen | SIEMENS | Germany |

| 3 | Inverter | SIEMENS | Germany |

| 4 | Screw Motor | SIEMENS | Germany |

| 5 | Air Switch | SIEMENS | Germany |

| 6 | Contactor | SIEMENS | Germany |

| 7 | SSR(Solid State Relay) | CARLO GAWAZZI | Switzerland |

| 8 | Wall Thickness Controller | MOOG | USA |

| 9 | Servo Valve | YUKEN | Japan |

| 10 | Hydraulic Valve | YUKEN | Japan |

| 11 | Solenoid Valve | YUKEN | Japan |

First, multi-layer mold design makes the wall thickness uniform and stable. Second,it can increase production efficiency by 5 times. Finally,the utilization rate of recycled materials increased by 4 times.

Customer Service

①Training

The buyer could dispatch their operators to the seller’s factory for training, including machine operation, maintenance & simple repairs;

Or against the requests of the buyer, the seller’s technician could train the buyer’s operators in the buyer’s factory in the periods of installing & adjusting;

②Installation & Adjustment

The seller could dispatch an engineer against the requests of the buyer to install and adjust the machines for one week(free of charge) in the buyer’s factory. After one week, if the buyer still needs the training,$100 should be paid for the engineer.

The buyer should make a reservation in advance before the delivery of the machines;

The buyer should pay for the engineer’s food & board while installation in the buyer’s factory. And the buyer should also pay for the air ticket for the engineer.

③Guarantee

The guarantee time is 1 year after the machines normally work in the buyer’s factory if only the problem is caused due to quality control or any reason by the seller. We will supply replaced parts free of charge and our engineers will guide you on how to solve the problems.