Septic Tank Blow Molding Machine

Septic tanks are basic sludge treatment facilities, as well as pretreatment facilities for domestic sewage.

The Yankang team has always insisted on technological innovation, and on this basis, new blow-molded new products have been developed, such as canoes, solar inner, mobile toilet, floating solar, floating dock, and septic tank blow molding machines, and so on.

Applications of Septic Tank Blow Molding Machine

Septic tanks are basic sludge treatment facilities, as well as pretreatment facilities for domestic sewage.

- Ensure the sanitation of living communities and avoid the spread of domestic sewage and pollutants in the living environment.

- In the anaerobic and decayed working environment of septic tanks, kill the eggs of mosquitoes and flies.

- The temporary storage of sludge, organic sludge undergoes anaerobic decay, mature organic sludge can be used as agricultural fertilizer.

- Pretreatment of domestic sewage (primary treatment), precipitate impurities, and hydrolyze macromolecular organic matter into small molecular organic matter such as acid and alcohol, and improve subsequent wastewater treatment.

Technical Parameter of Septic Tank Blow Molding Machine

| Septic Tank Blow Molding Machine | ||

| Specifications | 2 layers | |

| Extruders | Screw Diameter | ∮100/100 |

| Motor | 90/90kw | |

| Plasticizing Capacity | 450 kg/h | |

| L/D | 32/1 | |

| Max Screw Speed | 60 RPM | |

| Die Head | Accumulator Capacity | 94kg |

| Heating Load | 90kw | |

| Max. parison Weight | 94kg | |

| Clamping Unit | Clamping Platen Size | 2100*2200mm |

| Clamping Force | 2200 KN | |

| Mould Thickness | 1000-2200mm | |

| Hydraulic System | Hydraulic Drive Motor (Main) | 45kw |

| Hydraulic Drive Motor (Parison Control) | 7.5kw | |

| Oil Tank Capacity | 1200L | |

| Machine Weight | 65 Ton | |

| Dimension | L*W*H | 12m*4.5m*7.2m |

| Total Power | 350kw | |

| Average Power Consumption | 250kw | |

Configuration of Septic Tank Blow Molding Machine

For example:

Use original SIEMENS control systems. Guarantee high quality, safe and stable operation. At the same time, it provides after-sales international services.

For more advanced configurations, please refer to the following figure.

| SR | Description of Parts | Brand | Origin |

| 1 | PLC | SIEMENS | Germany |

| 2 | Touch Screen | SIEMENS | Germany |

| 3 | Inverter | SIEMENS | Germany |

| 4 | Screw Motor | SIEMENS | Germany |

| 5 | Air Switch | SIEMENS | Germany |

| 6 | Contactor | SIEMENS | Germany |

| 7 | SSR(Solid State Relay) | CARLO GAWAZZI | Switzerland |

| 8 | Wall Thickness Controller | MOOG | USA |

| 9 | Servo Valve | YUKEN | Japan |

| 10 | Hydraulic Valve | YUKEN | Japan |

| 11 | Solenoid Valve | YUKEN | Japan |

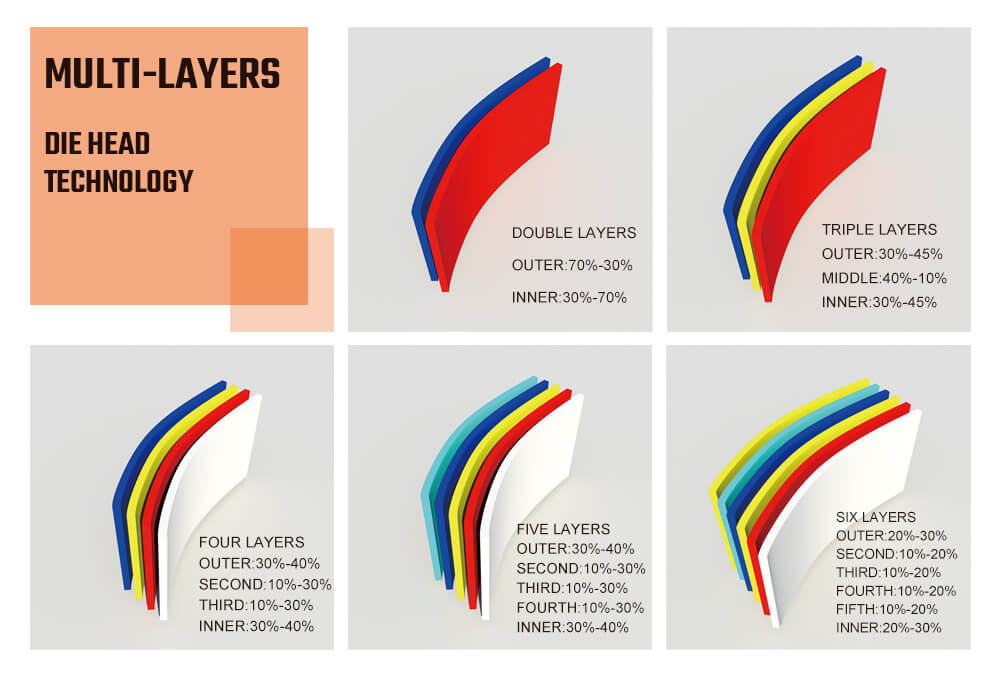

First, multi-layer mold design makes the wall thickness uniform and stable. Second,it can increase production efficiency by 5 times. Finally,the utilization rate of recycled materials increased by 4 times.

Customer Service

①Training

The buyer could dispatch their operators to the seller’s factory for training, including machine operation, maintenance & simple repairs;

Or against the requests of the buyer, the seller’s technician could train the buyer’s operators in the buyer’s factory in the periods of installing & adjusting;

②Installation & Adjustment

The seller could dispatch an engineer against the requests of the buyer to install and adjust the machines for one week(free of charge) in the buyer’s factory. After one week, if the buyer still needs the training,$100 should be paid for the engineer.

The buyer should make a reservation in advance before the delivery of the machines;

The buyer should pay for the engineer’s food & board while installation in the buyer’s factory. And the buyer should also pay for the air ticket for the engineer.

③Guarantee

The guarantee time is 1 year after the machines normally work in the buyer’s factory if only the problem is caused due to quality control or any reason by the seller. We will supply replaced parts free of charge and our engineers will guide you on how to solve the problems.