Investing in a storage blow molding machine is a significant decision for any manufacturing operation, and ensuring the longevity and optimal performance of its key components, particularly the head, is essential.

In this article, we’ll explore valuable tips for maintaining the head of a storage blow molding machine to enhance efficiency and extend its service life.

1. Regular Cleaning and Inspection

Routine cleaning and inspection of the machine head are fundamental to preventing issues and maintaining its functionality. Remove any residue or contaminants that may accumulate during production to ensure smooth operation. Regular visual inspections help identify wear, damage, or potential issues early on.

2. Lubrication is Key

Proper lubrication is crucial for the smooth functioning of the machine head. Regularly check and lubricate moving parts as specified in the manufacturer’s guidelines. This not only reduces friction and wear but also contributes to the overall efficiency of the machine.

3. Monitor and Maintain Temperature Control

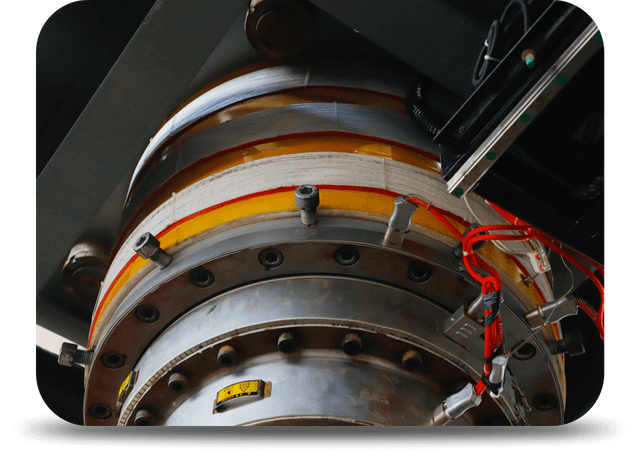

The temperature control system of the machine head plays a pivotal role in the blow molding process. Regularly monitor and calibrate temperature settings to ensure accurate and consistent heating. This not only improves the quality of the molded products but also prevents overheating-related damage to the machine head.

4. Address Wear and Tear Promptly

Over time, wear and tear are inevitable, but addressing them promptly is crucial. Replace worn-out components such as seals, gaskets, and nozzles to maintain the integrity of the machine head. Timely replacements prevent larger issues and production downtime.

5. Follow the Manufacturer’s Guidelines

Adhering to the manufacturer’s guidelines for maintenance is paramount. The manufacturer provides specific recommendations for cleaning, lubrication schedules, and replacement intervals. Following these guidelines ensures that the machine head operates within its intended parameters.

6. Conduct Periodic Performance Checks

Regularly assess the overall performance of the storage blow molding machine, specifically focusing on the head. Check for any irregularities in the molding process, such as uneven wall thickness or product defects. Identifying and rectifying performance issues early on can prevent extensive damage to the machine head.

7. Training for Machine Operators

Ensuring that machine operators are well-trained in the proper operation and basic maintenance of the storage blow molding machine is vital. Knowledgeable operators are more likely to identify and address issues promptly, contributing to the overall health of the machine, including its head.

8. Invest in Quality Spare Parts

When replacement parts are needed, opt for high-quality, OEM (Original Equipment Manufacturer) components. Using genuine spare parts ensures compatibility and maintains the machine’s reliability. It may be tempting to choose cheaper alternatives, but the long-term benefits of quality components far outweigh the initial cost savings.

Effectively maintaining the head of a storage blow molding machine is a combination of regular upkeep, adherence to manufacturer guidelines, and a proactive approach to addressing issues.

By implementing these tips, manufacturers can ensure the longevity and optimal performance of their blow molding equipment, ultimately contributing to a more efficient and reliable production process.