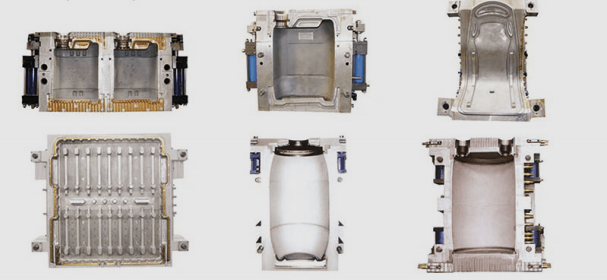

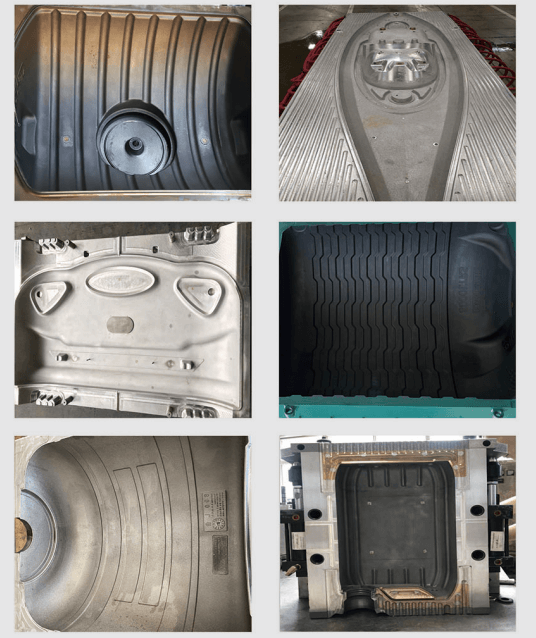

With modern science and technological advancement, new blow-molded products and packaging materials are continuously emerging, and the design and manufacturing of various blow molding molds are entering a phase of rapid development.

Currently, the research and development of blow molds is primarily focused on several key areas:

1. Automatic Trimming Technology

The automatic transition to flying edges has significantly contributed to enhancing the production efficiency of blow molding machines while alleviating the labor intensity for operators. The application scope of such molds is set to expand continuously.

2. High-Quality Surface Molding Technology

The increasing demands for the surface quality of packaging materials and blow-molded products have driven advancements in manufacturing technologies that achieve high surface quality. Consequently, the proportion of high-quality surface molds is anticipated to rise.

3. Point-Specific Negative Pressure Molding Technology

Many industrial blow-molded products have stringent wall thickness and surface quality requirements, and even strict mold control often fails to meet these technical specifications. The blow molding of products with significant variations in blow ratio imposes higher demands on molds. The ongoing research into point-specific negative pressure technology for blow molds is one of the methods aimed at addressing the challenges posed by products with large discrepancies in blow ratios, and it is expected that this approach will see increased research and application.

4. Various Three-Dimensional Molding Technologies

Three-dimensional blow molding technology is an effective method for producing irregular industrial components. As the market for irregular blow-molded products continues to expand, molds designed for three-dimensional blow molding will undergo rapid development and practical application.

5. Special Blow Molding Product Forming Technology (Including Preforming Technology)

The forming technology for special blow-molded products has reached a relatively mature stage, particularly in the area of preforming technology. This technique allows for the shaping of certain specialized blow-molded products, as well as those that are difficult to form using conventional blow-molding methods. As the application of preforming technology expands, it is expected to continue evolving and improving.

6. Deep Stretch Blow Molding Die Technology

The deep stretch blow molding technology, when combined with high-quality surface techniques, can produce specialized blow-molded containers that are challenging to create using standard blow molding methods. This technology is anticipated to experience rapid development in the coming years. The integration of multi-layer blow molding technology with liquid phase change ballistic protection technology may also showcase unique advantages in the production of blow-molded containers requiring special protection, as well as in the manufacturing of inter-wall blow-molded products.

The vigorous promotion and application of these advanced blow molding technologies not only enhance the design and manufacturing processes of various blow molding molds but also accelerate the innovation and upgrading of a wide range of blow-molded products.

It is expected that with the further development and application of these high-tech solutions, the manufacturing cycle for various blow molding molds will shorten, production costs may decrease, and the quality of mold manufacturing will see significant improvements.