There are many varieties and specifications of extrusion blow molding machines, and each major manufacturer of hollow molding machines, both domestically and internationally, has its naming methods.

The naming methods for extrusion blow molding machines are quite diverse, but currently, there are three main categories in common use:

The first category is the scientific naming method;

The second category is the manufacturer naming method;

The third category is the equipment characteristics naming method.

(1) Scientific Naming Method

The scientific naming method can be broadly divided into two types: the Pinyin naming method and the English naming method.

① Pinyin Naming Method

In this method, the first letter of the Pinyin for “plastic,” “blow molding,” and “machine” is used as the prefix for the name, followed by the volume capacity of the container that the equipment can process. For example, the SCJ1000 hollow molding machine manufactured by **Company is a plastic blow molding machine capable of producing containers with a volume of 1000 liters.

② English Naming Method

This method uses the capital letters BM from “blow molding machine” as the name. For instance, the BM230 manufactured by **Company also refers to a blow molding machine, which can produce containers with a volume of 230 liters. Using the English naming method makes it easier for foreign customers to choose when the equipment is exported.

(2) Naming Convention for Factory Names

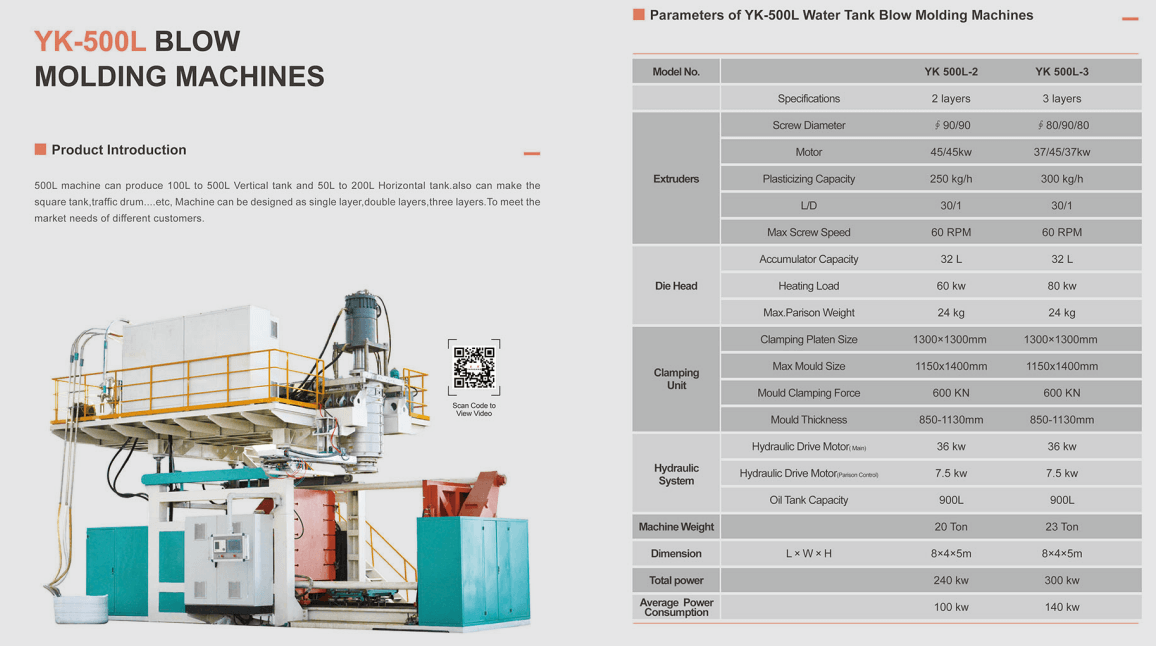

The naming convention for factory names, also known as the company name naming method, focuses on the first letters of representative characteristic nouns in the company’s name, combined with the volume capacity of the equipment that can blow mold containers. For instance, the YK-500L produced by Yankang Plastic Machinery Co., Ltd. signifies a blow molding machine made by Yankan, capable of producing containers with a volume of 500L (i.e. Y-Yan, K-Kang).

(3) Equipment Feature Naming Method

Some hollow-forming machines stand out due to distinct features compared to similar machines, leading manufacturers to name them based on these characteristics. For example, HTⅡ-18L indicates a high-speed, dual linear guide, dual station hollow forming machine capable of molding 18L containers. Additionally, it’s worth noting that blow molding machines are now primarily named according to the volume capacity of the containers they can produce, rather than by screw diameter. Industry professionals should take note of this shift.