Blow molding is a versatile and widely used manufacturing process for producing hollow plastic products such as bottles, containers, and tanks. The efficiency and quality of blow molding are significantly influenced by the type of blow molding machine used.

Understanding the different types of blow molding machines can help manufacturers choose the right equipment for their specific needs.

This comprehensive guide explores the various types of blow molding machines, their applications, and key features.

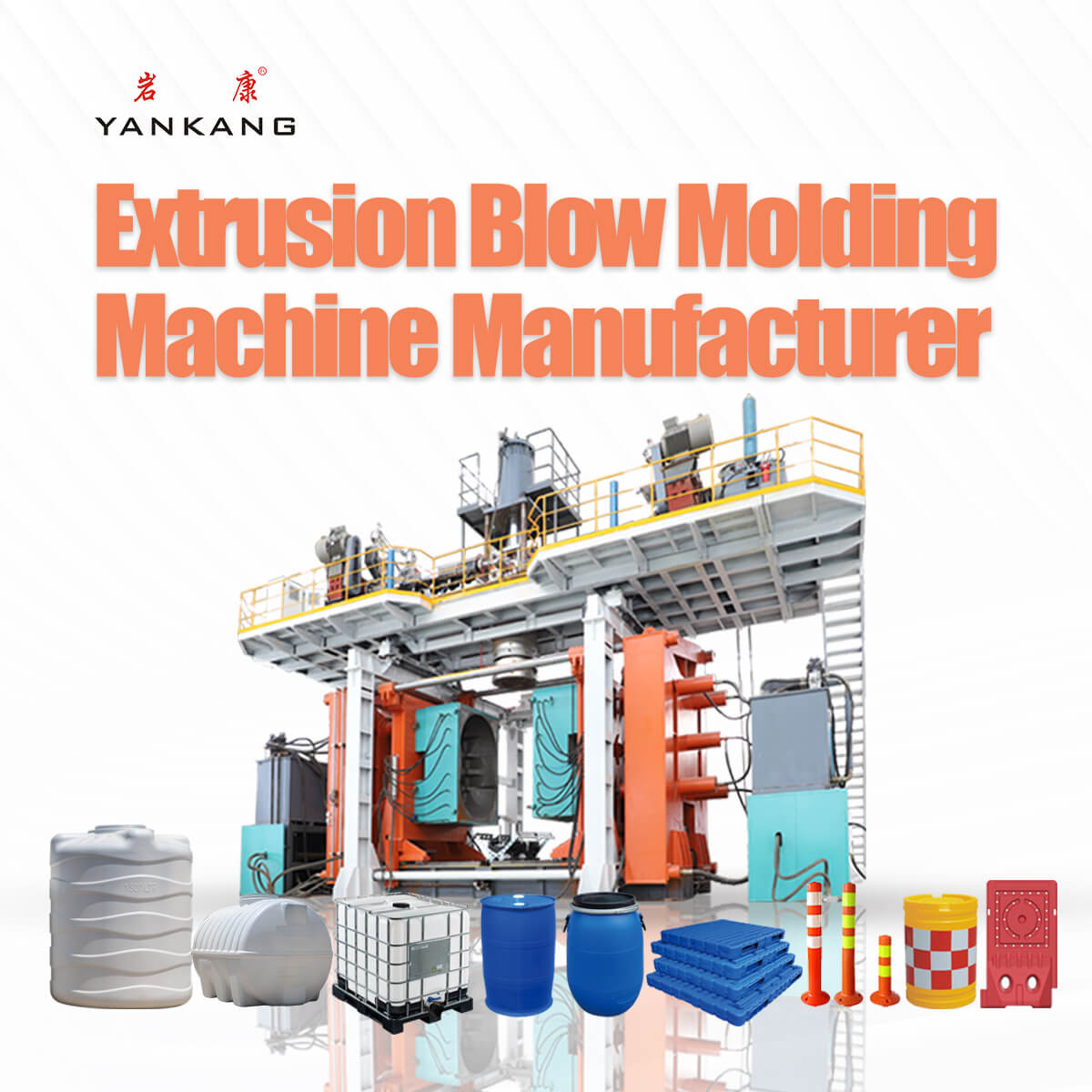

1. Extrusion Blow Molding (EBM) Machines

Extrusion blow molding machines are among the most common types of blow molding equipment. The process involves extruding a molten tube of plastic (parison), which is then captured in a mold and inflated to form the desired shape.

①Applications

– Bottles for beverages, detergents, and oils

– Large containers such as drums and tanks

– Automotive parts like fuel tanks and ducting

②Key Features

– Suitable for producing complex shapes with handles

– Capable of processing a wide range of plastics, including HDPE, PP, and PVC

– High production rates and flexibility

2. Injection Blow Molding (IBM) Machines

Injection blow molding machines combine injection molding and blow molding processes. The plastic is first injected into a preform mold to create a preform, which is then transferred to a blow mold and inflated.

①Applications

– Pharmaceutical and cosmetic bottles

– Small medical devices

– Containers requiring high precision and clarity

②Key Features

– High precision and uniform wall thickness

– Ideal for small to medium-sized containers

– Suitable for materials like PET, PP, and HDPE

3. Stretch Blow Molding (SBM) Machines

Stretch blow molding machines are used to produce high-strength, lightweight containers. The process involves stretching the preform both axially and radially before blowing, which enhances material strength.

①Applications

– PET bottles for beverages (water, soda, juices)

– Containers for personal care products

– Lightweight packaging solutions

②Key Features

– Produces containers with excellent clarity and strength

– High production speeds

– Ideal for creating thin-walled, lightweight containers

4. Reciprocating Blow Molding Machines

Reciprocating blow molding machines are designed for high-volume production. The extruder reciprocates horizontally to form the parison, which is then captured and blown into shape.

①Applications

– Large-volume production of bottles and containers

– Industrial and household chemical packaging

②Key Features

– High-speed production capability

– Suitable for producing a wide range of container sizes

– Efficient for high-volume manufacturing

5. Co-Extrusion Blow Molding Machines

Co-extrusion blow molding machines allow the production of multi-layered plastic products. Multiple extruders feed different materials into a single parison, creating layers with distinct properties.

①Applications

– Packaging for food and beverages with barrier properties

– Fuel tanks with chemical resistance

– Containers requiring multiple material layers for enhanced performance

②Key Features

– Ability to combine different materials for specialized applications

– Enhanced barrier properties and product protection

– Customizable layer configurations

6. Continuous Extrusion Blow Molding Machines

Continuous extrusion blow molding machines continuously extrude the parison, which is intermittently captured and blown into shape. This type of machine is ideal for high-efficiency production.

①Applications

– High-volume production of small to medium-sized bottles

– Industrial packaging solutions

②Key Features

– Consistent production flow

– Suitable for high-speed manufacturing environments

– Capable of producing uniform products

Choosing the Right Blow Molding Machine

Selecting the appropriate blow molding machine depends on several factors, including:

– Product Specifications: Consider the size, shape, and material requirements of the product.

– Production Volume: Determine the required production capacity and choose a machine that meets those needs.

– Material Compatibility: Ensure the machine can process the intended plastic materials.

– Budget and Investment: Evaluate the cost of the machine, including maintenance and operational expenses.

– Technological Features: Look for advanced features such as automation, control systems, and energy efficiency.

Understanding the different types of blow molding machines is essential for manufacturers aiming to optimize their production processes and meet specific product requirements.

By considering factors such as product specifications, production volume, and material compatibility, businesses can select the right blow molding machine to achieve high efficiency, quality, and profitability in their manufacturing operations.