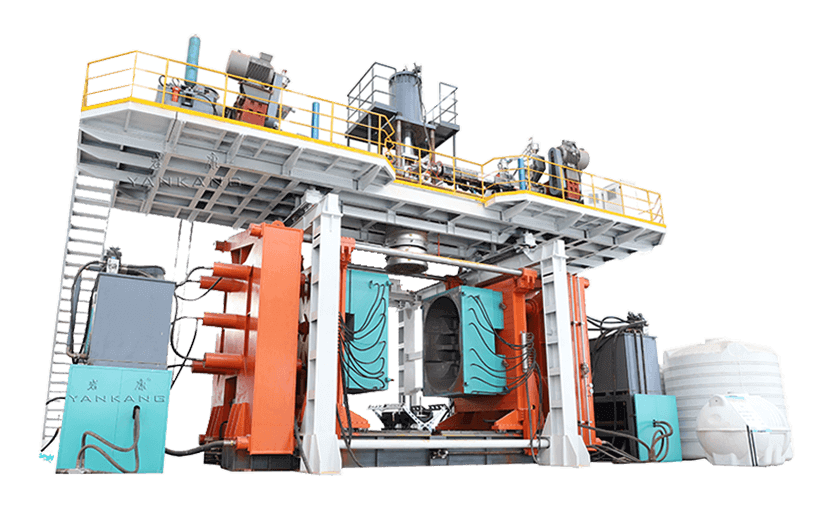

Water tank blow molding machines are specialized machines that are designed to manufacture high-quality water tanks. They are widely used in various industries that require large quantities of water tanks, such as agriculture, construction, and manufacturing.

In this article, we will discuss the characteristics of water tank blow molding machines and their applications in daily life.

Characteristics of Water Tank Blow Molding Machines:

- High Production Efficiency: Water tank blow molding machines can produce water tanks with high efficiency. They are equipped with advanced technology and have high automation levels that allow them to produce products at a rapid speed.

- Flexibility: These machines are highly flexible and can produce water tanks with different sizes, shapes, and capacities. This enables manufacturers to produce water tanks that match their specific requirements.

- High Precision: Water tank blow molding machines are designed with high-precision technology. They are capable of producing water tanks that are highly accurate in terms of shape, size, and capacity.

- Low Energy Consumption: Modern water tank blow molding machines are highly energy-efficient. They consume less energy compared to other types of machines.

- Cost-effective: Water tank blow molding machines are cost-effective, and they offer a lower production cost compared to other production methods. The cost of production is reduced because of the low energy consumption, high automation level, and fast production speed.

Application of Water Tank Blow Molding Machines in Daily Life:

- Agriculture: In agriculture, water tanks are required to store water for irrigation purposes. These tanks can be produced using water tank blow molding machines.

- Construction: In construction, water tanks are needed for the storage of water for construction purposes, such as mixing cement. Water tank blow molding machines can be used to produce these tanks.

- Manufacturing: In manufacturing, water tanks are needed for the storage of liquid products, including chemicals, oils, and other liquids. These tanks can be produced using water tank blow molding machines.

- Residential Use: In daily life, water tanks are used for storage of water for household use. Water tank blow molding machines can be used to produce these tanks in different sizes and capacities.

In summary, water tank blow molding machines are efficient, flexible, precise, energy-efficient, and cost-effective production machines. They are widely used in various industries for the production of water tanks. Their application is not limited to industrial purposes but extends to daily life, where water tanks are required for various uses. Water tank blow molding machines offer a solution for the production of high-quality tanks that match the specific requirements of manufacturers and households.