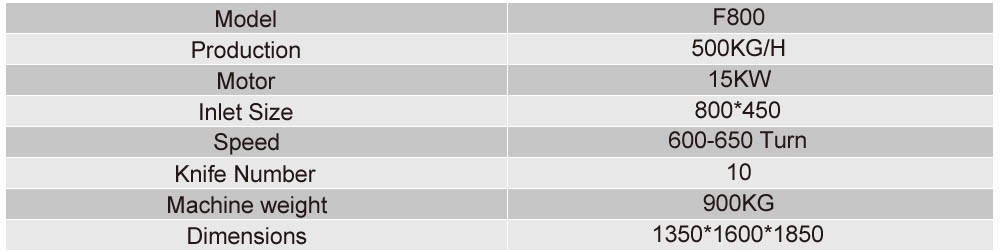

Plastic crusher, as its name suggests, is a crusher of broken plastic material.

But there is a question.

Is your crusher used correctly?

This article is to share with you about the crusher related knowledge.

Not much to say, let us go straight to the subject.

First, we need to know what a CRUSHER is.

At the same time as the raw materials of the blow molding machine or the granulator are produced, the defective products and the nozzle materials can be put into the edge plastic crusher in time. After pulverization is OK, and the pulverization is kept clean and dry, in the case of the ratio of the “two-material proportional valve”, the raw material and the nozzle are pulverized and mixed and molded, and the product is manufactured and recycled.

The advantage of the “crushing proportion mixing recovery system” formed by the plastic crusher combined with other auxiliary machines (drying machine, dehumidifier, chiller, mold temperature machine, etc.) is that the water product is not contaminated. The physical properties of the plastic – the strength, density, and color luster are protected from damage, so the quality of the product can be improved. Its benefits include cost and material savings, automated process management improvements, enhanced competitiveness, and a clean shop floor environment.

Then we divided the crushers into three categories.

The plastic crushers on the market today can be roughly classified into the following three categories:

(1) Hard plastic crusher, this machine is suitable for crushing all kinds of small and medium-sized plastic sheets:

1.ABS, PE, PP board, and other plates are crushed and recycled.

2. The rectangular feeding port specially designed for the smashing of the plate material facilitates the smashing of the long strip type plate and improves the working efficiency. The optional suction fan and storage barrel form a plate crushing and recycling system to fully utilize the recovery efficiency.

3. The use of sealed bearings, so that the bearing rotation is kept good for a long time; the knife type design is reasonable, the product is evenly granulated; the knife seat heat shrinking treatment, the shape design is beautiful and generous.

(2) Powerful plastic crusher:

1. The blade type structure is between the claw knife and the flat knife, which is suitable for crushing plastic products such as ordinary sheets, pipes, profiles, plates, and packaging materials.

2.general-purpose plastic pulverizer, using sealed bearings, so that the bearing rotation is kept good for a long time; the knife type design is reasonable, the alloy steel blade is used, the product is evenly granulated; the knife seat is heat-shrink, and after strict balance test, the shape design Beautiful and generous.

(3) Plastic pipe plastic crusher:

1. It is suitable for crushing all kinds of small and medium-sized plastic pipes, such as PE, PVC pipe, silicon core pipe, and other pipe crushing and recycling.

2. The circular tube type feeding port specially designed for the crushing of the pipe material facilitates the input and smashing of the long pipe and improves the working efficiency. Optional suction fan, storage barrel to form a pipe crushing and recycling system can fully utilize the recycling efficiency.

3.the use of sealed bearings, so that the bearing rotation is kept good for a long time; the knife type design is reasonable, the product is evenly granulated; the knife seat heat shrinking treatment, the shape design is beautiful and generous.

Next, let’s take a look at the precautions for using the crusher.

1. Before starting, you should manually move the drive wheel one or two times to confirm that the movement is flexible and start-up. Wait until the crusher is running normally.

2. Before stopping the operation, stop the feeding and drain the material in the machine before cutting off the motor power.

3. Pay attention to the temperature of the bearing during operation, so that the bearing maintains a good lubrication state, and pay attention to whether the sound and vibration are abnormal. When an abnormal condition is found, stop it and check if it is caught by an object that is not easily broken or if the machine is damaged.

4. Keep the feeding of the crusher even and prevent overload. Prevent unbreakable objects such as metal and wood from falling into the machine. When it cannot be broken, the moisture content of the feed should not be too high; when it is broken by the wet method, it is necessary to maintain an appropriate amount of water to prevent clogging due to insufficient flushing and reduce the production capacity.

5. Check if the particle size of the broken product meets the requirements. If there are too many particles exceeding the specified size, the cause should be found (such as excessive gap of the screen, too wide discharge opening, hammer wear, etc.) and appropriate measures should be taken to eliminate it.

6. When the crusher stops, check whether the fastening bolts are firm and how worn the wearable parts are. For the tooth crusher, the parking opportunity should also be used to remove the wood sandwiched between the teeth.

7. Parts that are worn out should be replaced or repaired in time.

8. The safety device of the crusher should be kept in good condition, and it must not be saved, and the safety device should be invalidated.

Finally, Yankang shared with you the maintenance and maintenance of the plastic crusher.

1. The plastic crusher should be placed in the ventilation position to ensure the heat dissipation of the motor and prolong its life.

2. The bearings should be regularly lubricated to ensure the lubrication between the bearings.

3. Check the tool screws regularly. After using the new plastic crusher for 1 hour, use the tool to fasten the moving knife and fix the screw of the knife to strengthen the fixing between the blade and the tool holder.

4. In order to ensure the sharpness of the cutting tool, the tool should be inspected frequently to ensure its sharpness and reduce the unnecessary damage of other components caused by the blunt blade.

5. When changing the tool, the gap between the movable knife and the fixed knife: 0.8MM for the crusher above 20HP is better, 0.5MM for the crusher below 20HP is better. The thinner the recycled material, the gap can be adjusted appropriately.

6. Before the second start, the remaining materials in the machine room should be removed to reduce the starting resistance. The inertia cover and the pulley cover should be opened regularly to remove the ash outlet under the flange to prevent the plastic crusher chamber from discharging the powder into the shaft bearing.

7. The machine should be well-grounded.

8. Regularly check whether the plastic crusher belt is slack and adjust it in time.

The above is the knowledge about the crusher shared by Yankang.

Have you learned that?

To learn more about blow molding machines, click on the blow molding machine blog.