Are you still using a traditional resistance heater? Do you know the induction heater? Why not choose it? Maybe you really need to know more about the induction heater.

The heater is an important part of the blow molding machine. The purpose of heating is to melt the plastic and form the material embryo. The plasticizing rate of plastics can be increased by proper temperature. In the pursuit of high efficiency and energy saving in today’s society, many blow molding machine manufacturers are still using the traditional way of resistance heating.

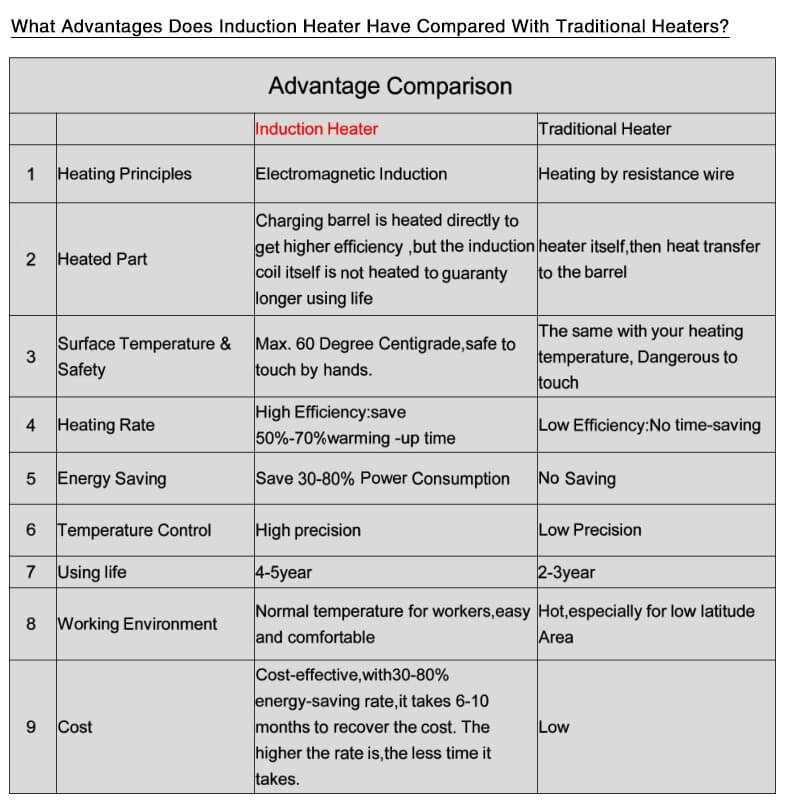

Today Yankang compares the advantages and disadvantages of these two heating methods.

Disadvantages of Traditional Resistance Heater

1. Large heat loss: the traditional heating mode, is the resistance wire winding, double-side heating circle of inside and outside, the inside (close to the cylinder part) of heat transfer into the cylinder, outside, most of the heat lost to the air, causing direct losses and waste of electricity.

2.Environmental temperature rise: due to a large amount of heat loss and the increase of ambient temperature, some enterprises have to use air conditioning to reduce the temperature, resulting in the secondary waste of energy.

3.A large quantity, short service life: maintenance due to using resistance wire heating, electric heating tube the heating temperature up to 300 degrees, thermal hysteresis is bigger, not accurate temperature control, resistance wire is easy to burn out due to high-temperature aging. The service life of a commonly used electric heating coil is about half a year.

4. The service life is short and the maintenance quantity is large. Due to the use of resistance wire heating, its heating temperature is as high as 300 degrees. It is difficult to control temperature accurately because of the large thermal lag, and the resistance wire is easy to burn out due to high-temperature aging. The service life of commonly used heating coils is about half a year, so the workload of maintenance is relatively large.

5. Because of the high temperature in the workshop and the increase of the oil temperature of the machine, the service life of the oil seal and the oil pump is greatly shortened, and oil leakage and pressure instability occur.

Although resistance heating is the earliest and simplest way of heating. However, with the improvement of technology, people’s demand for heating is also getting higher and higher. In addition to a good heating effect, it also needs enough energy-saving and environmental protection. Obviously, the performance of the traditional resistance heater is not suitable for the current technical requirements.

Advantages of Induction Heater

1.Long service life: induction heating will not generate heat due to the coil itself, and the service life is long. No maintenance and replacement costs are required. The heating part adopts a circular cable structure, the cable itself does not generate heat and can withstand a high temperature above 500 ℃. The service life is up to 10 years, with no maintenance cost.

2.Safe and reliable: the outer wall of the material barrel is heated by high-frequency electromagnetic action, and the heat is fully utilized, and there is basically no loss. Heat accumulates in the inner part of the heating body, and the surface temperature of the electromagnetic coil is slightly higher than that of room temperature.

3.High efficiency and energy saving: the internal heating method, direct induction heating body internal molecular magnetic energy and heat, warm start very fast and the average preheating time than the circle of resistance heating mode to shorten by more than 60%, and the thermal efficiency can reach above 90%.

4. It does not need all heating, but local heating can be chosen. So the workpiece deformation is small and the power consumption is small.

5. Heating without dead angle, the heated body is uniformly heated, and the electromagnetic coil can keep cool.

6.Accurate temperature control: the coil itself does not heat up, the thermal resistance is small, the thermal inertia is low, the internal and external wall temperature of the material cylinder is consistent, and the temperature control is real-time and accurate. Obviously improve product quality, high production efficiency.

7.Good insulation: the electromagnetic coil is wound with customized special high-temperature and high-voltage special cable, with good insulation performance.No direct contact with the outside wall of the tank, no leakage, short circuit fault, safety.

8. Stable running can meet long-term working needs.

9. Strong adaptability, it is suitable for working in all kinds of climates.

10. Anti-jamming, there is only one electromagnetic coil in the equipment, so there will be no interference between two or more coil magnetic lines and the problem of high power and low efficiency caused by power offset.

11. Improve working environment: there is no heat loss, and the surface temperature of the equipment can be improved to human touch. It can improve the working environment of the production site, increase the enthusiasm of the production workers, and reduce the cost of ventilation and cooling in the factory in summer.

In general, the induction heater has the advantages of energy-savings, high efficiency, long lifetime, high accuracy, and other good performance. Comparatively speaking, the induction heater is more suitable for production. In addition to improving production efficiency, it can greatly save production costs for us, thereby expanding our revenue. Yankang Plastic Machinery adopts Induction Heater for The Die Head and Extruders of Blow Molding Machine. It can save 40%-50% of energy.

How does induction heater save 30%-70% energy on plastic machinery?

1. Compared with resistance heating, the induction heater has an extra layer of the insulation layer, and the heat energy utilization rate increases.

2. Compared with resistance heating, induction heater directly ACTS on the material tube heating, reducing heat transfer heat loss.

3. Compared with resistance heating, the heating speed of the induction heater is more than one quarter faster, which reduces the heating time.

4. Compared with resistance heating, the heating speed of the induction heater is fast and the production efficiency is improved. The motor is in a saturated state, which reduces the power loss caused by high power and low demand.

The above is the traditional resistance heater and induction heater advantages and disadvantages comparison, is it clear?

So, do you want to continue using traditional resistance heaters?

Tomorrow, Yankang will continue to share with you the things of the blow molding machine, please look forward to it!