What kinds of heads are used for hollow blow molding machines? In what situations does each apply? There are three kinds of heads used for blow molding, one is a common pipe head, one is a material storage cylinder head, and the other is a parison adjusting head. These three heads are respectively used in the following three situations.

Below I will give you a brief introduction.

The types and applications of three common hollow blow molding heads:

1. Ordinary tube head

The structure of the ordinary tubular head is simple and the working process is simple, but when blowing molding products, it is easy to produce uneven thickness.

2. Storage cylinder head

It is suitable for the production of large-scale products. Usually, the large-scale hollow blow molding products adopt the storage cylinder type head, and the volume can be 1KG-240KG. Especially in the blow molding products above 300L, the blow molding head of the storage cylinder type will be selected.

3. Parison adjusting head

The thickness of the parison can be adjusted, and the product uniformity is good, but the structure of the machine head is complicated.

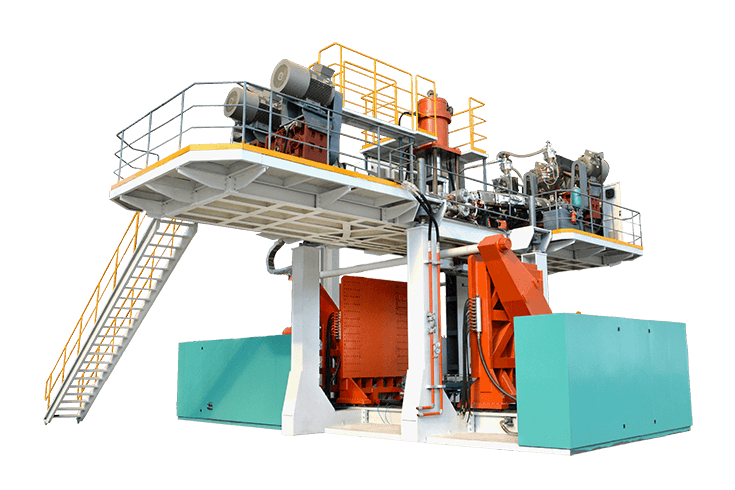

Yankang hollow blow molding machine can produce 100L-25000L hollow blow molding products, and the control point can reach 150 points. Applicable to all kinds of plastics: polyethylene, polyvinyl chloride, polypropylene, polyester, etc., common materials can be used.

At present, the production process of hollow blow molding machines can be divided into extrusion blow molding and injection blow molding. The newly developed ones include multi-layer blow molding and stretch blow molding. Blow molding machines can be divided into three categories: extrusion blow molding machines, injection blow molding machines and special structure blow molding machines.

The common extrusion hollow blow molding machine is a combination of the blow molding process and mold clamping machinery. consist of.

Yankang Hollow Blow Molding Opportunity chooses the suitable blow molding machine head for everyone according to the needs of the owner and designs a complete hollow blow molding machine scheme in detail. If you have requirements regarding the production process, please call Yankang to inquire about relevant technical solutions and quotations.