What are the commonly used blow molding methods? The hollow blow molding process is divided into extrusion blow molding, injection blow molding, stretch blow molding, and stretch blow molding has two kinds of blow molding processes: extrusion stretch blow molding and injection stretch blow molding. What are the characteristics of blow molding?

This article will give you a detailed summary.

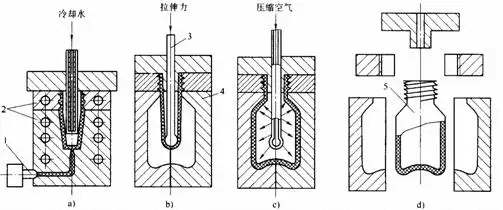

1. Blow Molding Methods-extrusion blow molding

It is suitable for various types of plastics, with high production efficiency, uniform parison temperature, and low product breakage rate, and can produce many large-scale hollow blow molding products, with small equipment investment, high return efficiency, and low operating costs.

It is suitable for various types of plastics, with high production efficiency, uniform parison temperature, and low product breakage rate, and can produce many large-scale hollow blow molding products, with small equipment investment, high return efficiency, and low operating costs.

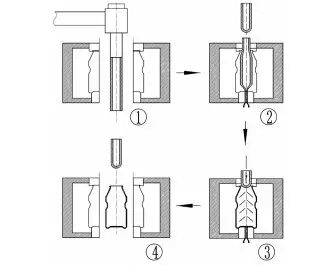

2. Blow Molding Methods-injection blow molding

Injection blow molding process, two-step blow molding method of the hollow blow molding machine, suitable for processing relatively large and small containers or wide-mouth containers, the characteristics of injection blow molding equipment are the design requirements of cavity and mandrel, mandrel The diameter is smaller than the minimum diameter of the neck of the blow-molded container, which is very convenient for shelling. The diameter of the container should be made as small as possible, and the inflation ratio will not be too small.

Injection blow molding process, two-step blow molding method of the hollow blow molding machine, suitable for processing relatively large and small containers or wide-mouth containers, the characteristics of injection blow molding equipment are the design requirements of cavity and mandrel, mandrel The diameter is smaller than the minimum diameter of the neck of the blow-molded container, which is very convenient for shelling. The diameter of the container should be made as small as possible, and the inflation ratio will not be too small.

Injection blow molding has high relative molecular weight and melt viscosity, and is less affected by shear rate and processing temperature.

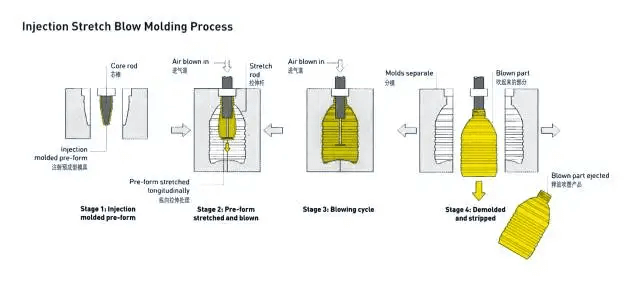

3.Blow Molding Methods-stretch blow molding  Stretch blow molding is divided into the hot parison method and the cold parison method, which can be used to process PVC, PP, PET, RPVC, and other materials. The production characteristic of the stretch blow molding process is to control the temperature of the parison below the melting point. Under the temperature, the principle of biaxial stretching is used to improve the strength of the product.

Stretch blow molding is divided into the hot parison method and the cold parison method, which can be used to process PVC, PP, PET, RPVC, and other materials. The production characteristic of the stretch blow molding process is to control the temperature of the parison below the melting point. Under the temperature, the principle of biaxial stretching is used to improve the strength of the product.

The stretch blow molding process is suitable for thermoplastics and can control resin plasticizing temperature, product shape, precision, and production efficiency.

The above are three common hollow blow molding processes. If you have purchase requirements for hollow blow molding machines, please contact Yankang blow molding machines.