Do you know about the custom blow molding machine? Are you looking for a customized blow molding machine? or Do you want to have your own blow molding machine?

Here is detailed guidance about What, Why, How of it.

What’s the custom blow molding machine?

In short, custom blow molding machine is according to different plastic blow molding products standard and produce different blow molding machine and blow molding moulds.

The custom blow molding machine is based on the different types of plastic products to produce.

Different products, customization plans are also different.

Why choose a custom blow molding machine?

With the development of blow molding technology, blow molding products get more widespread use.

The customer’s need is also getting higher and higher.

At the same time, there are many different specifications that demand to plastic blow molding products.

According to different product requirements, a custom blow molding machine appears.

The custom blow molding machine can better meet the production needs of different customers.

How custom blow molding machine?

How to accomplish a custom blow molding machine?

Actually, a custom blow molding machine should according to the parameter of blow molding products.

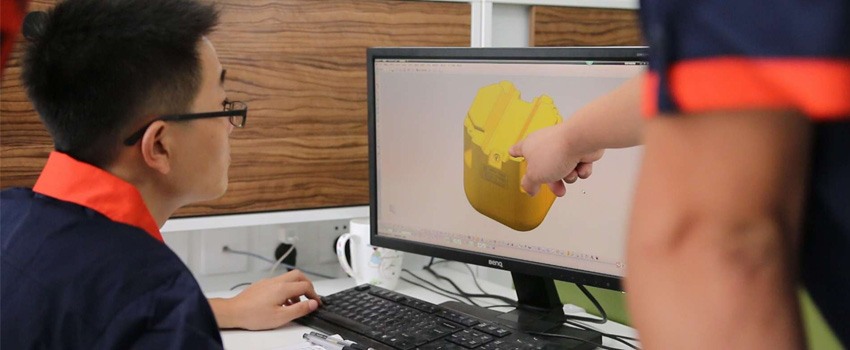

When the blow molding machine manufacturers receive the requirements of customers, the technical team will make a blow molding machine manufacturing plan.

How to do with a custom blow molding machine manufacturer?

When you find a Reliable Custom Blow Molding Machine Manufacturer, you should prepare parameters related to products that you will produce. Tell this information and your requirements to the manufacturer. The manufacturer will custom machine plans according to your needs.

Custom blow molding machine mainly including custom machine and custom molds.

Custom machines refer to design different parameters, control systems, and performance of the machine according to different blow molding products.

Custom molds refer to design different shapes, sizes of molds according to different blow molding products.

What’s the parameter of blow molding products?

Including shape, size, length, weight, area, height, etc.

What’s the purpose of a custom blow molding machine?

The custom blow molding machine satisfies customers’ different product needs to the greatest extent and expands the product range of the blow molding machine.

Yankang as a leading blow molding machine manufacturer in China, we devoted to improving product quality all the time. At the same time, it provides a complete blow molding customization service.

Common Water Tank

The common water tank generally has a vertical tank, horizontal tank, loft water tank, etc.

Except for shape differences, there is also the capacity difference.

We can provide custom blow molding machine and blow molding mold according to customer’s demand.

Other Blow Molding Products

IBC Tank, Plastic Pallet, Double Ring Drum, Floating Dock, Road Barrier, Kayak, Septic Tank, Solar Inner, and so on.

This is the blow molding machine that Yankang Plastic Machinery can provide at present. More types of blow molding machine will be developed in the future.

The above blow molding products are special shape products for special use. Production is different from common water tanks.

And the specification of these products is more diversified. Different country has a different standard.

To cater to the needs of customers and the market. We can provide suitable blow molding machine and mold according to customer’s requirements.

Besides, we support the Logo Customization service as well.

During mold production, the logo provided by the customer will engrave on the inner mold.

The final products with the logo.

Many people usually worried about the quality of the machine.

How to ensure the quality and performance of custom blow molding machine?

Actually, it’s the best way to finish all parts of blow molding machine production by the same team. Including installation and testing.

But most manufacturers can’t finish it because limited by the fund, technology, experience, and other aspects.

They’ll choose the part that they’re best at to finish. And find another manufacturer to finish other parts.

Finally, install all parts together.

That’s not bad. The advantage of doing so is to maximize the integration of the strengths of each manufacturer. You think it’s possible to achieve the best result of the blow molding machine.

But, there is a certain disadvantage for blow molding machines by a different team.

The ideas and thoughts of every team are different.

Although each machine part can up to great effect, the combination may not do it.

Because all parts of the blow molding machine need to cooperate with each other in operation.

It’s difficult for a machine to achieve the best effect to be used with different parts.

Thus, if you want a custom blow molding machine, keep in mind, choose a reliable manufacturer. It’s the best way.

Yankang Plastic Machinery focuses on the high-quality blow molding machine.

Except for the blow molding machine, we are also able to finish the blow molding molds by ourselves.

The blow molding machine mold plays an important role in the production.

We can provide relevant mold according to different product standards.

We can provide an auxiliary machine as well.

The blow molding machine consists of a pneumatic system, hydraulic system, cooling water system, circuit system, and autoloader system. These include a cooling chiller, cooling tower, air compressor, grinder, shredder, air tank, mixer, and so on.

Our engineer will make an economical and effective machine plan for the customer. And choose the suitable auxiliary machine and mold to meet the needs of the customer.

A custom blow molding machine is a better service. It caters to the development of the market and meets the diversified needs of the customer.

The particular note is that if you plan to choose blow molding machine customization. You should consider the manufacturer’s service combine with our own needs comprehensively. Choose the most suitable customization plan. In this way, the blow molding machine can up to the ideal effect that you expect.

Click to learn more information about Blow Molding Machine.

Hope To Help You.

Thanks For Reading.

want to know the know standard operating procedures for a blow molding machine

start up procedures

process parameters to be monitored

shut down procedures