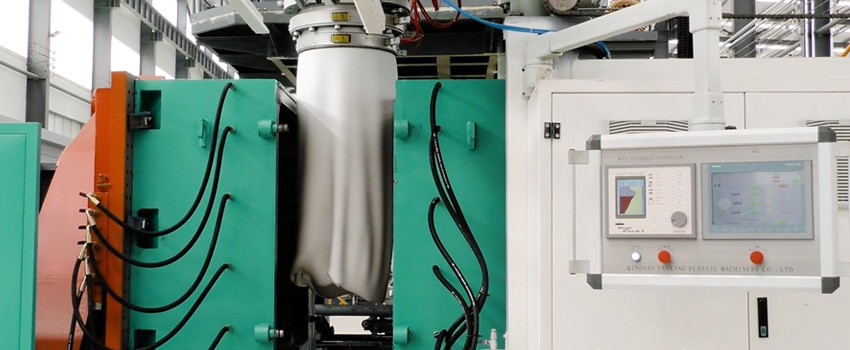

With the development of blow molding technology, the blow molding machine is becoming more and more advanced. Today, we will introduce in detail the plastic blow molding machine computer control.

Plastic Blow Moulding Machine Computer Control For Blow Molding Process

Display Process Parameters

The computer setting of all process parameters, intelligent input, and adjustment is necessary for blow molding machines to produce qualified plastic products.

On the touchable computer display screen, the error between the theoretical setting value and the actual value of the process parameters can be seen intuitively, and the error can be reduced by adjusting so that the optimal process parameters can be obtained in the shortest time.

The display of process parameters can be divided into three forms:

(1) Linear coordinates and curvilinear coordinates are used to show the trend of technological change.

(2) Display in the form of a histogram, which can stereoscopically display various technological performances.

(3) Display in the form of word number table to facilitate operators to directly refer to process parameters and verify errors.

Display The Machine Body Profile And Material Flow

Intelligent control of the blow molding machine is not only to display process parameters through a computer screen but also to reflect the overall situation of the current operation. Such as the axial profile and the material flow of the blow molding machine.

(1) The extrusion and material storage parts of the blow molding machine, as well as the state and flow of the material.

(2) The state and flow of the material storage part, the die, and the material.

(3) The main technological parameters of the axial section of the extrusion part and the storage part. Such as melting temperature and pressure etc.

(4) The clamping action of the clamping mechanism and the material flow during the clamping process.

By means of computer control, the working state of equipment and some main process parameters can be monitored in order to optimize the process and select the best conditions, thus greatly improving product quality and production efficiency.

Display Fault Diagnosis and Alarm

Once the equipment of the blow moulding machine breaks down, the computer will automatically start the analysis function, judge the fault location, type, and cause, and also provide the corresponding solutions.

In addition, through computer program editing, it can lock and open temporary protection automatically after abnormal operation and operation errors of the machine.

At the same time, it can remind the abnormal parts and determine the causes, so that the fault can be eliminated in time, and greatly shorten the maintenance time, which effectively guarantees production.

The computer control not only monitors the operation status of the blow molding machine in real-time but also intelligently controls the operation of the blow molding machine.

Intelligent Parameter Matching of Plastic Blow Moulding Machine

Before the operation of the blow molding machine, the operator can directly input some key data in the production process into the computer control system, and select the appropriate range of parameters. Through the intelligent parameter matching function to monitor the operation of equipment, the quality stability of plastic blow molding products can be effectively guaranteed.

Plastic Blow Moulding Machine Computer Control For Wall Thickness Control

In the blow molding process, an important factor affecting the quality of blow-molded products is whether the parison has uniform wall thickness.

With the continuous development of industrial technology, people put forward higher requirements for the uniformity of the wall thickness of plastic products, so controlling the uniformity of the wall thickness of plastic products has become the technical focus of the hollow blow molding process.

By using a computer to adjust the clearance of blank die in the circumferential direction, the wall thickness of blank and product can be well controlled.

Yankang Plastic Machinery adopts MOOG Wall Thickness Controller.

The wall thickness of plastic products is more uniform. The products are also more durable.

The plastic blow moulding machine computer control is also embodied in many other aspects.

In short, plastic blow moulding machine computer control brings a lot of convenience during the running. And improve the production efficiency of the blow molding machine and the quality of plastic products. Do you want to know more about the plastic blow molding machine? Please click to get more relevant BLOGS.

Thanks for Reading!