Blow Molding Machine VS Rotomoulding Machine

What is Blow Molding?

Blow molding is out from the extruder, is still in a state of softening tube thermal plastic blank into the forming die, and then into the compressed air, use air pressure to make along with the cavity deformation, blow to make a mouth, short neck insulating products.

What is Rotomolding?

Rotomolding is a multi-purpose process for manufacturing various hollow plastic parts. A single hollow part is produced by heating and rotating along two axes. The molten plastic is injected into the rotating mould. Centrifugal force forces the molten plastic to stick to the inner wall of the mould.

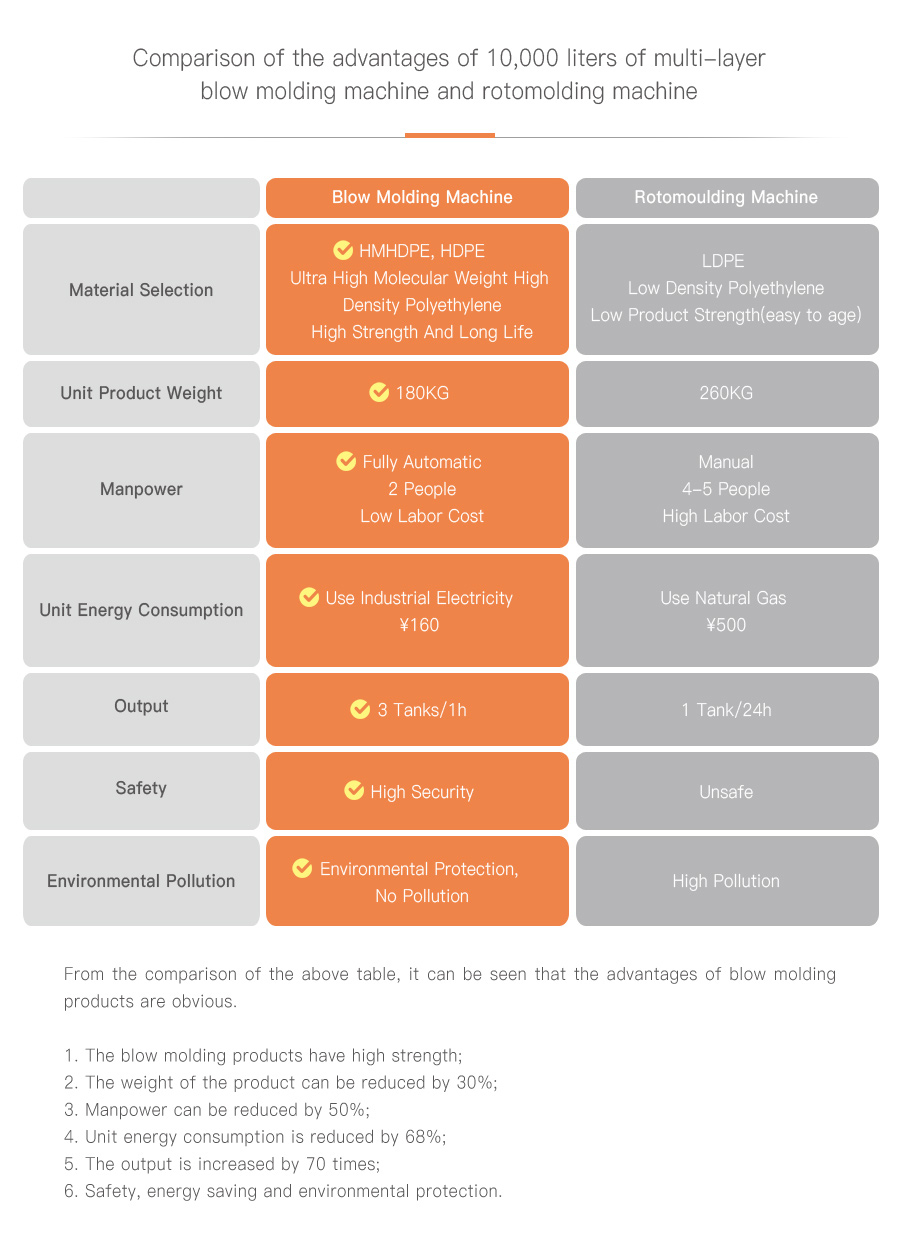

1. Comparison of the advantages of 10,000 liters of multi-layer blow molding machine and rotomolding machine

2. Blow Molding Machine Working Process

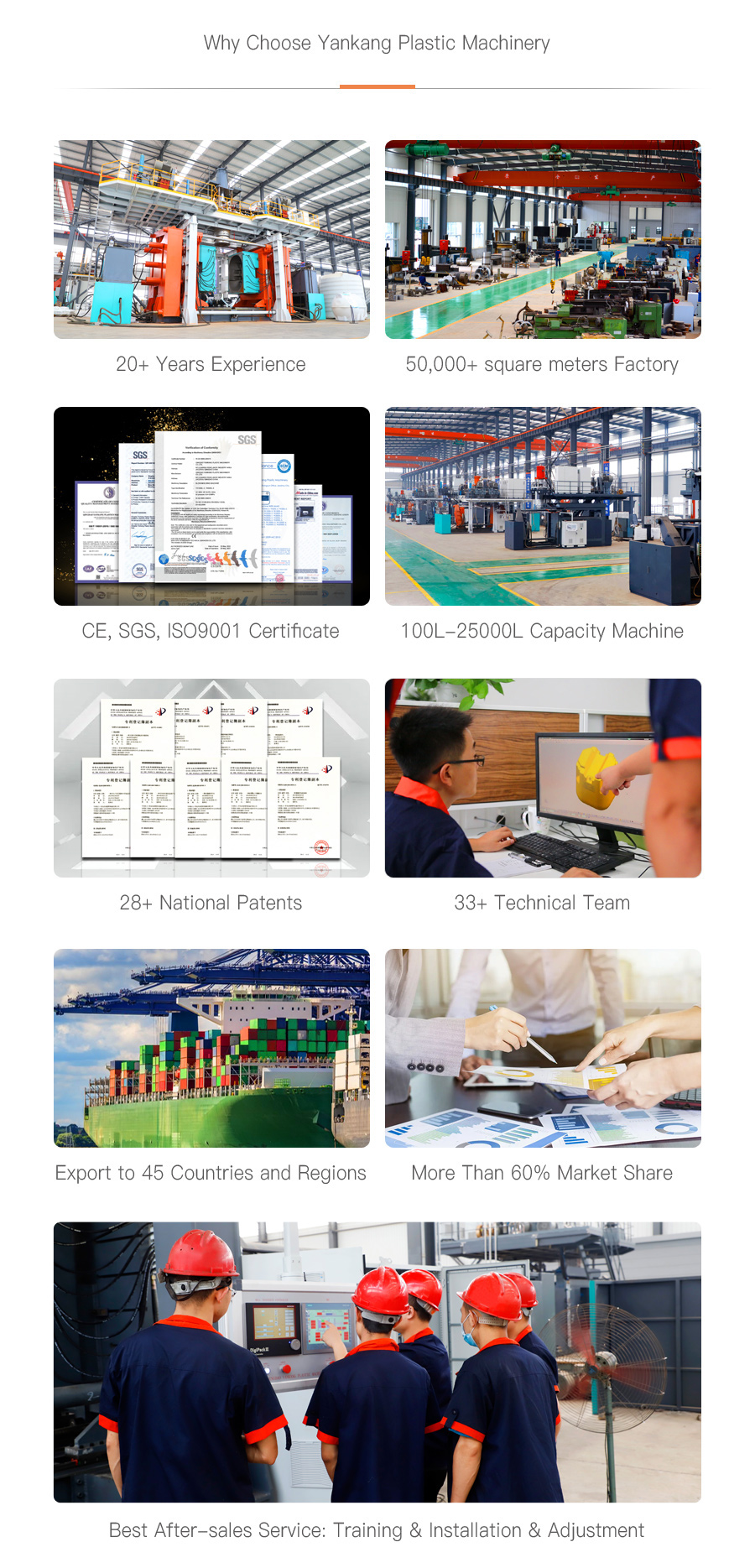

3. Why Choose Yankang Plastic Machinery?