Static electricity is a common phenomenon that occurs when there is an imbalance of electric charges on the surface of an object. In industrial processes, such as blow molding, the buildup of static electricity can have significant consequences.

This article aims to shed light on the role of static electricity during the operation of blow molding machines and its impact on the production process.

1. The Basic Working Principle of Blow Molding Machines

Blow molding is a widely used manufacturing process for producing hollow plastic objects, such as bottles and containers. It involves melting plastic material, typically in the form of small pellets or granules, and then shaping it into a desired form using air pressure.

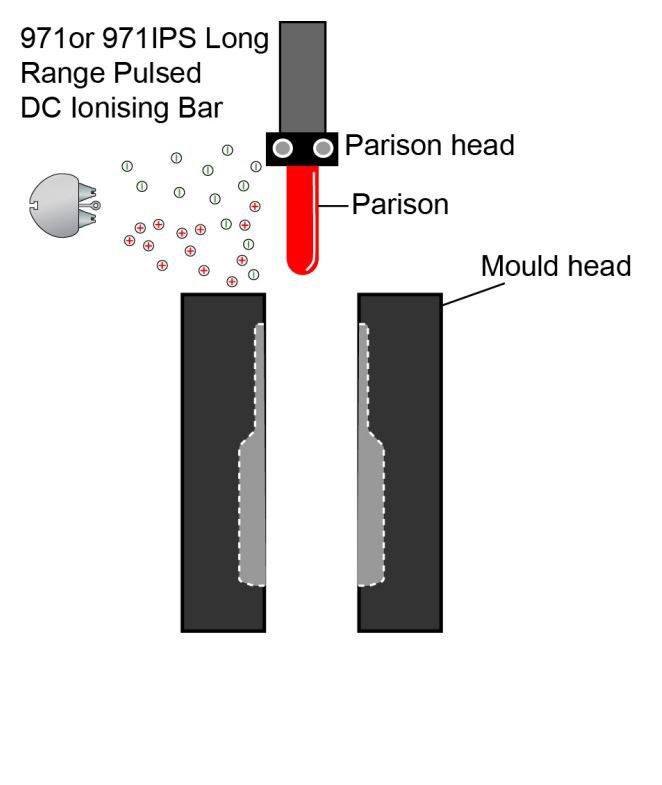

In a typical blow molding machine, the process involves three main stages: extrusion, parison formation, and blow molding. In the extrusion stage, plastic material is melted and forced through a die to form a continuous tube, known as a parison. The parison is then clamped between two halves of a mold, and the air is blown into it, causing the plastic to expand and take the shape of the mold. Finally, the molded object is cooled and ejected from the machine.

2. Static Electricity Generation and Accumulation

During the operation of blow molding machines, various factors contribute to the generation and accumulation of static electricity. These factors include friction between the plastic material and the machine components, rapid movement of the molten plastic, and the presence of insulating materials.

Friction between materials is one of the primary causes of static electricity. As the plastic pellets or granules move through the feeding system, they rub against each other and the machine’s surfaces. This friction leads to the transfer of electrons between the materials, resulting in an electric charge imbalance.

Rapid movement of the molten plastic during extrusion and molding processes also generates static electricity. The high-speed flow of the plastic material against the mold’s surface can induce charges, leading to static buildup.

Additionally, insulating materials, such as plastic or rubber components, tend to promote the accumulation of static charges. These materials restrict the flow of electrons and prevent charge dissipation, allowing static electricity to build up.

3. Impact on Blow Molding Process

Static can have several negative effects on the blow molding process, including production defects, safety risks, and increased downtime.

One of the most significant concerns is the attraction of airborne particles to the charged surfaces. Static charges can cause dust, fibers, or other contaminants to adhere to the plastic surface, resulting in visual defects or compromised product quality. These defects may affect the appearance, strength, and functionality of the final product, leading to customer dissatisfaction and potential rejections.

Furthermore, the discharge of static electricity through operators or sensitive electronic components can pose safety risks. In highly charged environments, operators may experience electric shocks, which can lead to injuries or even fatalities. The discharge of static electricity near electronic control systems or sensitive machinery can also cause malfunctions or damage.

Moreover, the accumulation of static electricity can cause interruptions in the production process. When charges build up on the plastic material or machine components, they can interfere with the proper movement and positioning of parts. This can result in jams, misalignments, or other mechanical issues, requiring manual intervention and causing production delays.

4. Mitigating Static Electricity in Blow Molding Machines

To minimize the negative impact of static electricity, several measures can be taken in blow molding machines:

1. Grounding: Proper grounding of the machine and its components helps to dissipate static charges and prevent their accumulation.

2. Ionization: Installing ionizing devices, such as ion blowers or bars, neutralizes static charges by emitting ions, which neutralize charges on the plastic surface.

3. Humidity control: Maintaining appropriate levels of humidity in the production environment can help reduce static electricity buildup. Dry environments tend to promote the accumulation of charges, while higher humidity levels aid in charge dissipation.

4. Anti-static materials: Incorporating anti-static additives or coatings into the plastic material can minimize the generation and transfer of static charges.

5. Regular maintenance: Ensuring proper cleaning and maintenance of the machine’s surfaces and components can help eliminate sources of friction and reduce static generation.

Static electricity is a common challenge faced during the operation of blow molding machines. Its accumulation can lead to operational issues, compromised product quality, and safety risks.

By understanding the factors contributing to static electricity and adopting appropriate mitigation measures, manufacturers can effectively manage this issue and enhance the overall efficiency and reliability of blow molding processes.