This is a frequently asked question: Why is the speed of the blow molding machine feeding different? No matter different feeding length or different feeding time, all comes down to the same reason, that is why is unstable blow molding machine feeding?

Unstable blow molding machine feeding is one of the common problems of the plastic blow molding machines. Unstable feeding will affect the product’s manufacturing process and product quality.

So, find the reason for unstable feeding is necessary. This blog will analyze the reason for this problem.

There are 3 reasons for unstable blow molding machine feeding.

You can judge it according to the different site situation.

Unstable Feeding of Blow Molding Machine Screw

This reason is for continuous blow molding machines. Because during the manufacturing process of a continuous blow molding machine, the prepared material will output into the mold directly. Thus, if the screw is wrong, the phenomenon of unstable feeding will occur.

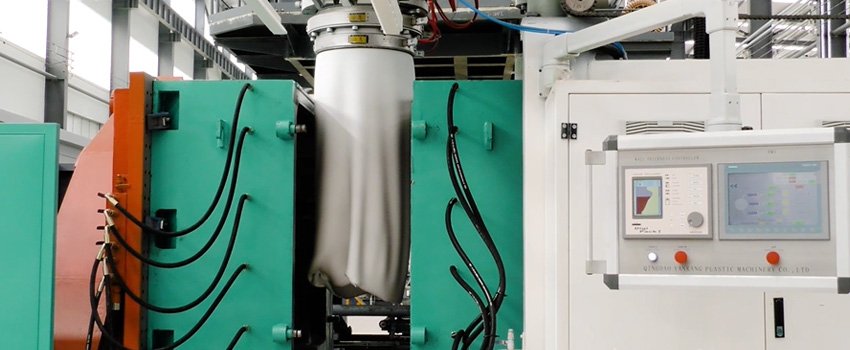

In turn, this reason doesn’t apply to the cylinder storage blow molding machine.

Cylinder storage blow molding machine, material extrusion is based on the production cycle of the product. The prepared materials are stored in the cylinder storage to a certain volume and entered into the mold through the die head. Therefore, the screw feeding wrong does not affect it.

Electromagnetic Interference

This point usually is for the servo valve and electronic ruler of the blow molding machine.

Once disturbed, there will be large or small fluctuations, which will affect normal operation.

The common source of electromagnetic interference is the inverter.

Once a problem occurs, the problem of the inverter can be eliminated first, and if there is a problem, it should be repaired or replaced immediately.

The electronic ruler of the blow molding machine is equivalent to a sliding rheostat, which can be used as a voltage divider in the hollow blow molding machine.

Electronic Ruler Is Faulty Or Polluted

The failure of the electronic ruler of the blow molding machine is generally disturbed. We have already mentioned in the previous content.

There are many reasons for the contamination of the electronic ruler of the blow molding machine. For example, because the electronic ruler is not sealed at the beginning, there may be some other impurities entering, which will affect the contact resistance of the brush and cause the digital number to jump, causing the electronic ruler to fail and unstable.

Electromagnetic interference, electronic ruler failure, or pollution are all control components or equipment of the blow molding machine. After the failure or interference, it affects the instability of the running state, so it is impossible to accurately control the blow molding machine feeding.

Unstable blow molding machine feeding not only is the common problem of the blow molding machine, but also a Common Problems Of The Products Quality.

Above is the reason for unstable blow molding machine feeding. Whatever the problem, finding the source is the key to solving it. From this, we can solve the problem more efficiently. If you have other problems with plastic blow molding machine. You can visit our Blow Molding Machine Blog to find guidance.