The reason and solution of the blow molding extrusion parison bending, wrinkling, cracking, etc. are the focus of this post.

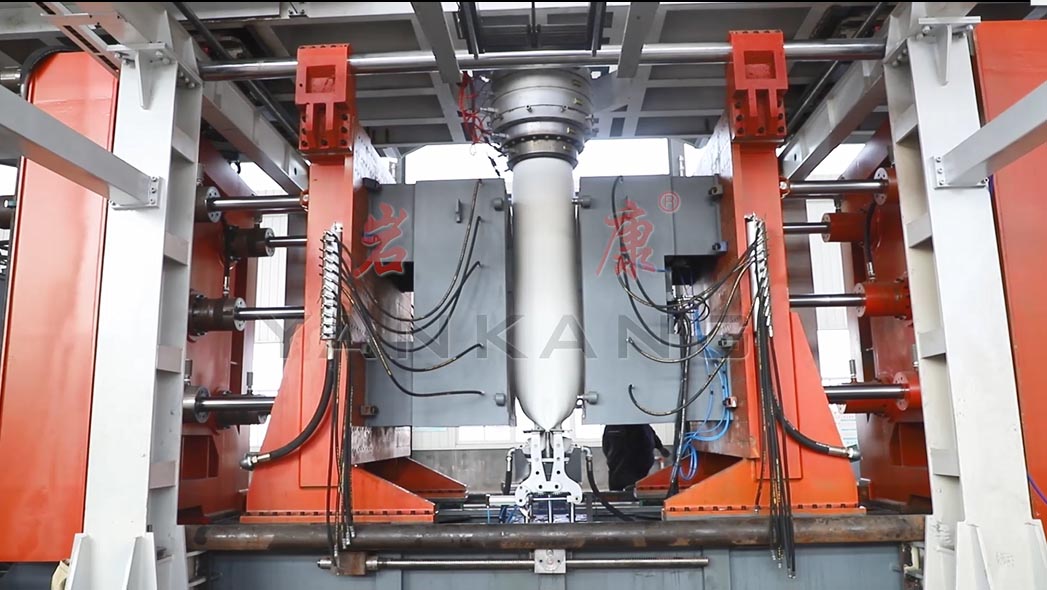

The tubular plastic parison obtained by extrusion molding of the thermoplastic resin is placed in a split mold while it is hot (or heated to a softened state). Immediately after the mold is closed, compressed air is introduced into the blow-extruded parison to blow the blow-extruded parison and cling to the inner wall of the mold. After cooling and demoulding, various hollow products can be obtained.

The importance of blow molding extruded embryos is obvious.

However, in the process of blow molding, there will be bending, wrinkling, cracking, and sagging of the blow molding extruded embryo.

How to solve these problems?

Don’t worry!

Why is the blow molding extrusion parison prone to bending? How should it be solved?

(1) The main reason for the blow molding extrusion parison bending

①The flow path in the machine head is not smooth or the center of the machine head is not aligned. The die gap is large on one side and small on the other, and the parison will bend toward the side with a small die gap.

②The uneven heating of the machine head makes the temperature of the molten material non-uniform, which causes the stretching action of the extruded parison to sag everywhere due to its weight.

③ The extrusion rate is too fast, which causes the melt to accumulate at the die and cause the parison to bend.

(2) Solution

①Check the flow path of the machine head, adjust the center of the machine head to make the gap between the die uniform.

②Adjust the heating temperature distribution of the machine head to make the heating of each part even.

③ Reduce the extrusion rate.

Why is there a curling phenomenon in the extrusion blow molding parison? How should it be solved?

(1) The main reason for the blow molding extrusion parison wrinkling

It is caused by the unreasonable temperature control of the machine head, which causes the difference in the temperature of the melt on the inner and outer surfaces of the parison.

①When the extruded parison appears to curl inward, the die temperature may be too high.

② If the parison is crimped to the outside, the core temperature may be too high.

(2) Solution

Control the temperature of the head die and core die to be consistent, and keep the temperature of each part uniform.

①When the extruded parison appears to be curved inward, the die temperature should be lowered.

② If the parison is crimped to the outside, the temperature of the core should be appropriately reduced.

Why does the extruded parison break easily during inflation? How should it be solved?

(1) The main reason for the rupture phenomenon

① The inflation ratio is too large. When the parison size and quality are fixed, the larger the blow-up ratio of the parison, the larger the container size. The thinner the wall thickness of the product, the raw material can be saved, but the inflation becomes difficult. The strength and rigidity of the product are reduced, and cracking is prone to occur.

② The parison is eccentric, the parison wall thickness is uneven, and the smaller wall thickness is prone to cracking under the same inflation ratio.

③ The extrusion rate of the parison is too slow, causing the parison to sag severely and uneven wall thickness.

④ Blow molding is too slow after clamping.

⑤ The parison has scratches.

⑥ Mixed with other raw materials or impurities.

(2) Solution

① Increase the weight of the product, increase the wall thickness of the product, and use a die of the appropriate size to reduce the inflation ratio.

②Adjust the die of the machine die head to make the wall thickness uniform (or set the MOOG wall thickness control chart according to the mold design).

③Adjust the pressure and flow of pressing material to speed up the pressing material. Or change to a more stretchable plastic.

④ It is possible to increase the pre-blowing air pressure properly and set the correct mold delay or blowing delay time.

⑤ Put a magnetic frame in each hopper to ensure that the source of recycled materials is clean.

⑥ Ensure the consistency of raw materials and ensure that the same type of plastic is always used, and the masterbatch used for blow molding is used.

As the most professional blow molding machine manufacturer, Yankang has rich experience in dealing with blow-molding machines.

Above is the blow molding extrusion billet appears the reason and the solution.

Thanks to the company’s rich experience and continuous technical innovation, the quality of the Yankang blow molding machine has been praised by customers at home and abroad.

The above is the reason and solution for the blow molding extrusion parison bending, wrinkling, cracking, and so on.

More information about the quality of extrusion blow molding parison:5 Factors Affecting the Quality of the Extrusion Blow Molding Parison

For more knowledge about blow molding, please follow the blow molding machine blog.

I enjoy, result in I found just what I used to

be looking for. You have ended my 4 day long hunt! God

Bless you man. Have a great day. Bye