Blow molding parison sagging is the focus of this post. In the article, you will learn about the factors and solutions that affect the blow molding parison sag.

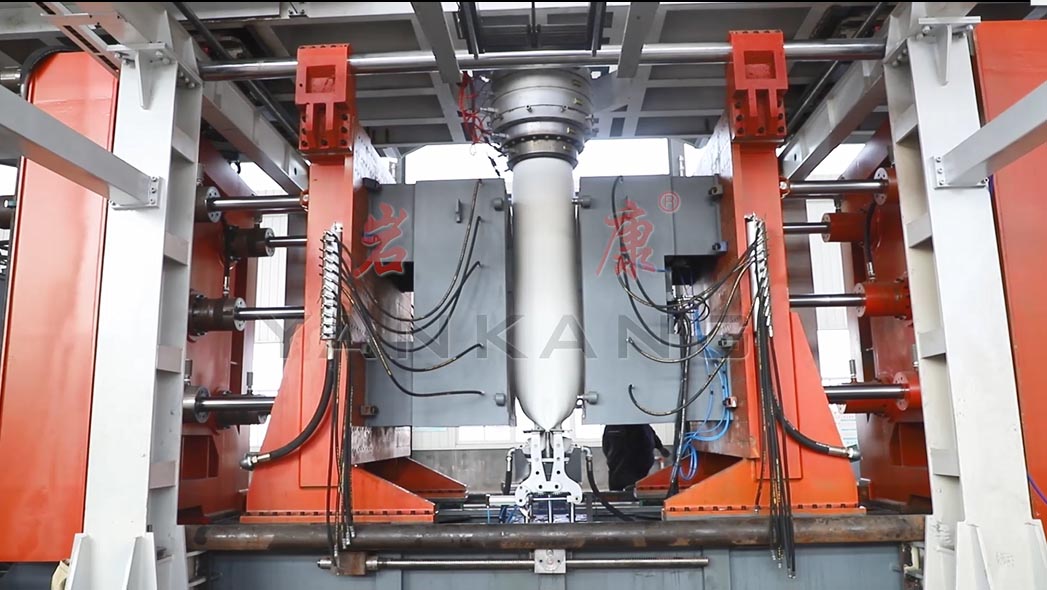

Due to the weight of the blow molding parison during the blow molding extrusion process, the blow molding parison is prone to sag, resulting in uneven wall thickness of the blow molding parison.

The more severe the sag, the greater the unevenness of the parison wall thickness.

Therefore, during the molding process, the sag of the blown parison must be strictly controlled.

Many factors affect the sag of the blow mold during the extrusion of the parison.

For example, the weight of the parison, extrusion time, melt viscosity, etc. These factors also affect the uniformity of parison wall thickness to varying degrees.

Factors influencing blow molding parison sag:

- The weight of the parison. As the weight of the parison increases, the parison sags due to its weight, so that the wall thickness of the parison becomes thinner.

- Melt viscosity. As the melt viscosity decreases, the sag of the parison increases. However, for materials with high melt viscosity, the parison sag is small (closely related to the fluidity of the raw material).

- Squeeze time. The extrusion time increases and the sag increases.

The above three are the common factors that affect the blow molding parison sag.

As a professional blow molding machine manufacturer, Yankang Plastic Machinery has accumulated very rich experience in various common problems that occur in blow molding machines.

Regarding the problem of blow molding embryo sag, Yankang summarized the following solutions.

Solutions for blow molding parison sag:

In the extrusion blow molding process, the factors that affect the parison sag often do not exist alone but affect each other.

Therefore, in production, the test should be conducted according to different brands of materials to determine the best molding process conditions. In this way, the self-weight sag of the parison is reduced, and the uniformity of the parison is improved.

If the parison sag is found to be severe during the production process, it can be handled in the following ways.

- Choose a resin with a relatively low melt flow rate. Fully dry the material and reduce the fluidity of the melt.

- The temperature of the die and mold can be appropriately increased to reduce the viscosity of the melt.

- Improve the extrusion efficiency to reduce the parison extrusion time.

- Speed up the mold closing speed to reduce the parison sag time.

- Properly increase the gap width of the die and increase the wall thickness of the parison.

The above is about the influencing factors and solutions of blow molding parison sag.

More information about the quality of the extrusion blow molding parison:5 Factors Affecting the Quality of the Extrusion Blow Molding Parison.

In the blow molding process, in addition to the sag of the blow molding sag, the blow molding extrusion mold often bends, wrinkles, and breaks. In the previous article, Yankang introduced the reasons and solutions for the bending, wrinkling, and cracking of the blow molding extrusion parison. Friends in need can click to view the above article.

To learn more about blow molding machines, please visit the blow molding machine blog.

It¦s actually a great and useful piece of info. I¦m glad that you just shared this helpful info with us. Please stay us informed like this. Thank you for sharing.

I am always thought about this, thanks for putting up.