20000L Super-Large Water Tank Blow Molding Machine

The 20000L super-large multi-layer blow molding machine is the largest and most advanced blow molding machine in the world and can be used to produce water tank from 1000L to 20000L in 1-6 layers.

IBC Tank Blow Molding Machine

IBC tank blow molding machine used to produce range from 200L to 2000L IBC tank. In order to ensure the kind of blow molding machines are better adapted to the market, with modular design make the blow molding machine to easy install,adopt the servo pump and induction heaters ,more energy efficient .

Road Barriers Blow Molding Machine

Road barrier blow molding machine used to produce different size road barrier,because the standard of every country is different ,so the YanKang company can use private customized methods according to customers’ different design requirements.

Plastic Pallet Blow Molding Machine

Plastic pallet blow molding machine used to produce different size pallets,because the standard of every country is different ,so the YanKang company can use private customized methods according to customers’ different design requirements.

Plastic Blow Molding Molds

The company can design hollow blow molds according to customer requirements, including vertical and horizontal molds of various capacities, various types of plastic pallet molds,road barrier molds of different sizes, IBC tank molds, floating tank molds and so on.

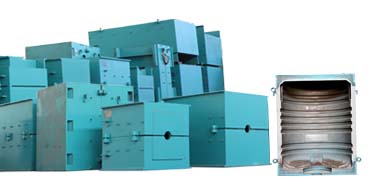

Cooling Tower

The Cooling Tower: Using the wind coming from the wind to form convection with the water from the top, the heat source is drained away, a part of the water evaporates in the convection, and takes away the corresponding latent heat of evaporation, thereby reducing the temperature of the water.

Air Compressor

The screw air compressor used by Yankang employs a high-capacity compression module, which has a low external-circle speed of the rotor and achieves optimal oil injection, achieving high efficiency and high reliability.

Mixer

The work of the vertical mixer is that the screw’s rapid rotation lifts the raw material from the bottom of the barrel to the top, and then throws it off in an umbrella-like fly and returns to the bottom. This way, the raw material is tumbling and stirring in the barrel and can be used in a short time. The uniform mixing of raw materials is completed.

Cooling Chiller

Chiller: the mold needs to forced cooling to improved the productivity of the products.In the process of rapid prototyping,mold need cooling as soon as possible in order to speed up finalize the design of products,so as to improve the yield and quality of products.

Shredder

Plastic crushers are generally used to crush various plastics and rubbers, and pellets can be directly used for extrusion as a raw material for production.Yankang blow molding machine and plastic crusher have the features of energy saving, energy saving, high crushing efficiency.